Transforming Supply Chain Performance Through Strategic BOM Optimization

Client Background

A leading $Billion technology market leader in mission-critical data center infrastructure, facing challenges in Bill of Materials (BOM) management across a complex product portfolio.

Challenges Faced

This section outlines the core difficulties and pain points the client was experiencing. It provides context on the hurdles that needed to be overcome before achieving the successful outcome.

Unmanageable BOM Complexity:

Thousands of components led to procurement inefficiencies, supplier risks, and excess inventory.

Extended Time-to-Market:

Disconnects between engineering and manufacturing delayed New Product Introduction (NPI).

Cost Leakage:

Material shortages, rush orders, and inconsistent pricing increased supply chain expenses.

Akraya’s Strategic Solution

To transform the supply chain performance, we implemented a comprehensive BOM optimization strategy aligned with supply chain best practices:

-

Strategic Component Rationalization:

Reduced unique SKUs by 30%; negotiated preferred supplier agreements (18% cost reduction); multi-sourced critical components.

-

Digital BOM Management Platform:

Real-time visibility; automated impact analysis; predictive shortage alerts; 25% reduction in engineering change orders (ECOs).

-

Lean Supply Chain Orchestration:

JIT subassembly delivery; optimized kitting; inventory pooling; 22% lower carrying costs at 99.5% material availability.

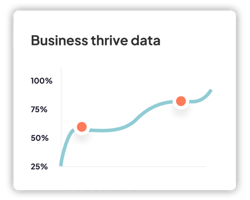

Measurable Outcomes

Operational

25% fewer ECOs; NPI cycle reduced from 12 to 8 months; on-time delivery improved to 98.5% (from 87%).

Financial

$3.2M annual procurement savings; $6.2M working capital unlocked; $780K annual disruption cost reduction.

Business

Enhanced resilience; lower emissions; faster market responsiveness.

Conclusion

Akraya’s BOM optimization transformed supply chain performance into a competitive advantage, delivering rapid ROI and sustained market leadership.